Metal Stamping Supply Chain Management

Wiegel offers service in all phases of metal stamping production from early design concepts to tooling to production of finished metal stampings. This is a critical business model we developed to allow customers to reduce their supply base and source the entire manufacturing process under one facility. Wiegel keeps a tight chain of suppliers that are thoroughly vetted through our approval process and qualifying audit which focuses on quality, price and delivery. We also track performance scoring of all suppliers based on critical quality metrics. We partner with highly qualified material suppliers to source quality raw material at cost-effective rates for competitive overall distribution costs, and we work with a small network of preferred suppliers for secondary applications such as plating, coating and finishing applications, welding and molding. When we take on new and existing programs, the movement of production through all levels of our supply chain is fully managed and led by our expert team of project managers assigned to those projects to ensure timing, delivery and other critical factors are always being met.

ORGANIZED PLANNING AND LOGISTICS

No matter where our customers are in the world, we are capable of managing the supply chain for production, handle and delivery of parts to any regional or international geographic location and to multiple locations. We plan and organize special processes custom developed by our process engineers to find the most efficient production process to fit our manufacturing customers’ project needs. You can rely on Wiegel to consistently ship and receive materialsand partsto arrive at production facilities on-time. When Wiegel is handling your program, materials and parts are always scheduled accordingly with reliable material suppliers and secondary process vendors so there are no breaks in the supply chain and we’re always ahead and in control of every time sensitive distribution flow.

We have a very systematic approach when it comes to transparent communication on project development between our project team and our customers. Our manufacturing customers are always kept informed with real-time updates on program status. We share Gantt charts with customers showing project development on a weekly basis and schedule frequent conference calls and meetings to keep all stakeholders aligned with goals and updates and confirm the project is moving through our timeline as planned. On-going part orders from existing customers are managed by our premier customer service team and can be tracked on our customer portal.

It’s our goal to simplify the metal stamping supply chain by offering a comprehensive range of stamping capabilities and supporting services and managing pre- and post-production operations for our manufacturing customers. This system saves our customers on project timing and production cost without compromising quality and customer requirements.

OUR PRODUCTION PARTS

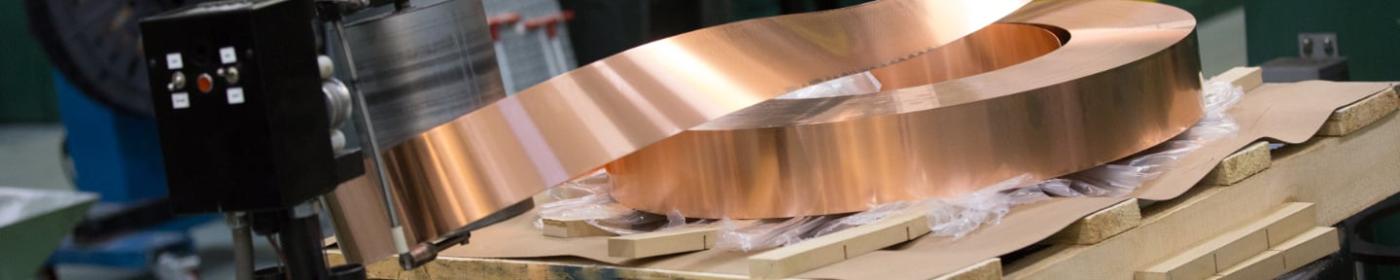

Wiegel produces a variety of precision metal stampings made from copper, precious metal and ferrous metals. We specialize in manufacturing of both precision electrical connectors and non-electrical parts that are used in our world’s most demanded consumer products and essentials.

Family owned and operated since 1941, we’ve designed and built tool and dies for a range of metal stampings and metal formed parts with tight tolerances and stringent requirements including:

- Brackets

- Busbars

- Clips

- Compression Limiters

- Crush Bushings

- Fasteners

- Fuse Boxes

- Fuse Clips

- Heat Sinks

- Hose Clamps

- Housings

- Inserts

- Lead Frames

- Lighting Components

- Press-fit Pins

- Rolled Bushings

- Selective Plated Lead Frames

- Selective Plated Terminals

- Shields

- Terminals, Contacts and Connectors

- Wire and Cable Connectors

INDUSTRIES WE SERVE

It’s our mission to offer premier metal stamping and metal forming solutions to the most challenging and innovative engineering product designs. We combine advanced metal stamping production and tooling equipment, superior quality controls, seamless automation and production processes and a knowledgeable and experienced team to serve an array of market segments.

We Prioritize customer satisfaction

At Wiegel, our utmost priority is customer satisfaction with the quality and integrity of our parts. In-die sensors, press monitoring systems, camera vision systems and a dedicated inspection team ensure parts leaving the production line exceed customer expectations.

Quality

With Zeiss CMMs, OGP smart scopes and dedicated sensor and camera vision system technology to monitor stamping parts in and off production lines, our customers know quality assurance is our number one priority. We are IATF and ISO certified and have a dedicated quality lab and inspection team responsible for maintaining quality control at the greatest extent.

Learn MoreSustainability

Wiegel is committed to production sustainability and efficiency. We train our team to conserve energy and resources and follow an ISO 14001 certified environmental management system that allows us to operate in an eco-friendly supply chain and stay compliant with industry standards.

Learn MoreOur Technology

Wiegel lives by the philosophy of embracing the latest technology. We have regular technology updates and new equipment acquisitions so we can always have the necessary tools to develop breakthrough techniques and processes and deliver quality parts.

Learn More