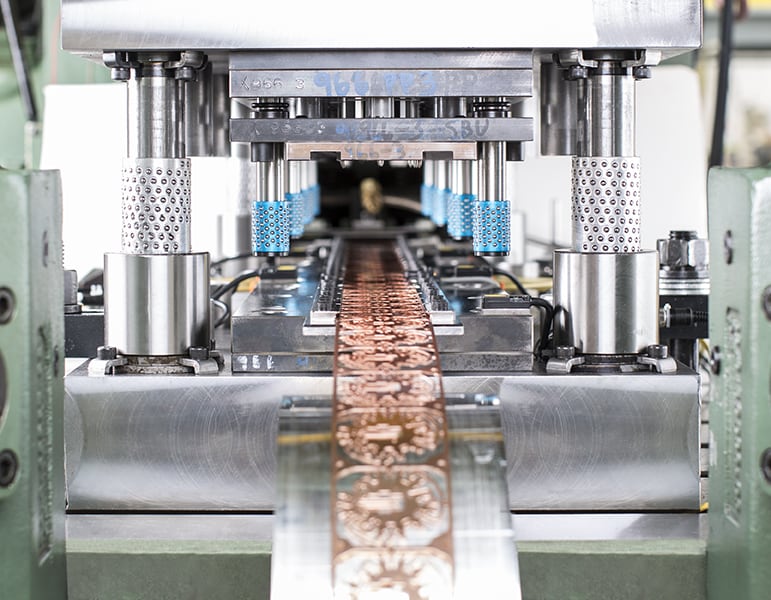

Stamped Parts

Wiegel produces a variety of precision metal stampings made from copper, precious metal, and ferrous metals. We produce stamping components such as busbars, brackets, electronic shielding components, lead frames, press-fit pins, terminals, wire and cable connectors, assemblies, and more. We specialize in the manufacturing of both precision electrical connectors and non-electrical parts that are used in our world’s most demanded consumer products and essentials.

Services

Progressive Die Heavy Stamping

Our progressive die heavy stamping department uses press equipment from Minster, a leading metal forming equipment solutions provider. Minster technology allows us to manufacture thicker and larger components that require larger tools and greater punch press bed sizes. Our heavy stamping department delivers reliable stamped parts that meet your unique specifications on time, every time.

Progressive Die High Speed Stamping

Our high-speed stamping department operates Bruderer presses to stamp copper-based alloys, aluminum, ferrous, and exotic metals at speeds up to 1,500 strokes per minute. This increased speed enables quick turnaround of multi-million-piece production programs. Progressive die high-speed parts are stamped while running multiple-up tooling progressions at tremendous speeds yielding cost-effective, high-quality parts for our customers.

Applications

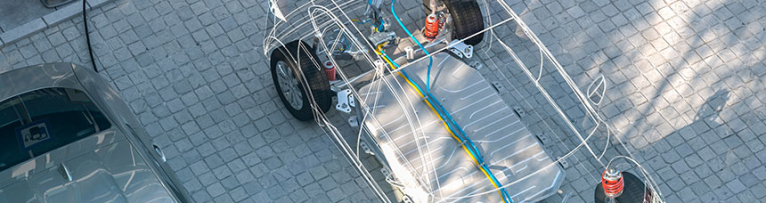

For decades, automotive manufacturers have relied on Wiegel’s stamping expertise for high precision, tight tolerance solutions. We produce stamped parts for some of the largest fuel powered and hybrid electric vehicle (HEV) tier-manufacturers and OEMs.

Lighting/LED manufacturers choose Wiegel to manufacture terminals, housings, brackets, metal face plates, and mounting plates for commercial, residential, infrastructure and stadium lighting solutions.

Wiegel supplies the world’s most innovative and revolutionary electric power transmission and distribution products for leading electrical equipment manufacturers.

The electric vehicle industry is evolving with new technology advances and eco-friendly, sustainable products for a battery-powered future. Wiegel is heavily involved in supplying precision electric vehicle metal stampings for groundbreaking EV power systems.

Wiegel ensures smooth and efficient process integration between metal stamping production and our customers’ plastic insert and injection molding processes so delivery times are always met and part quality is never compromised.

.png)